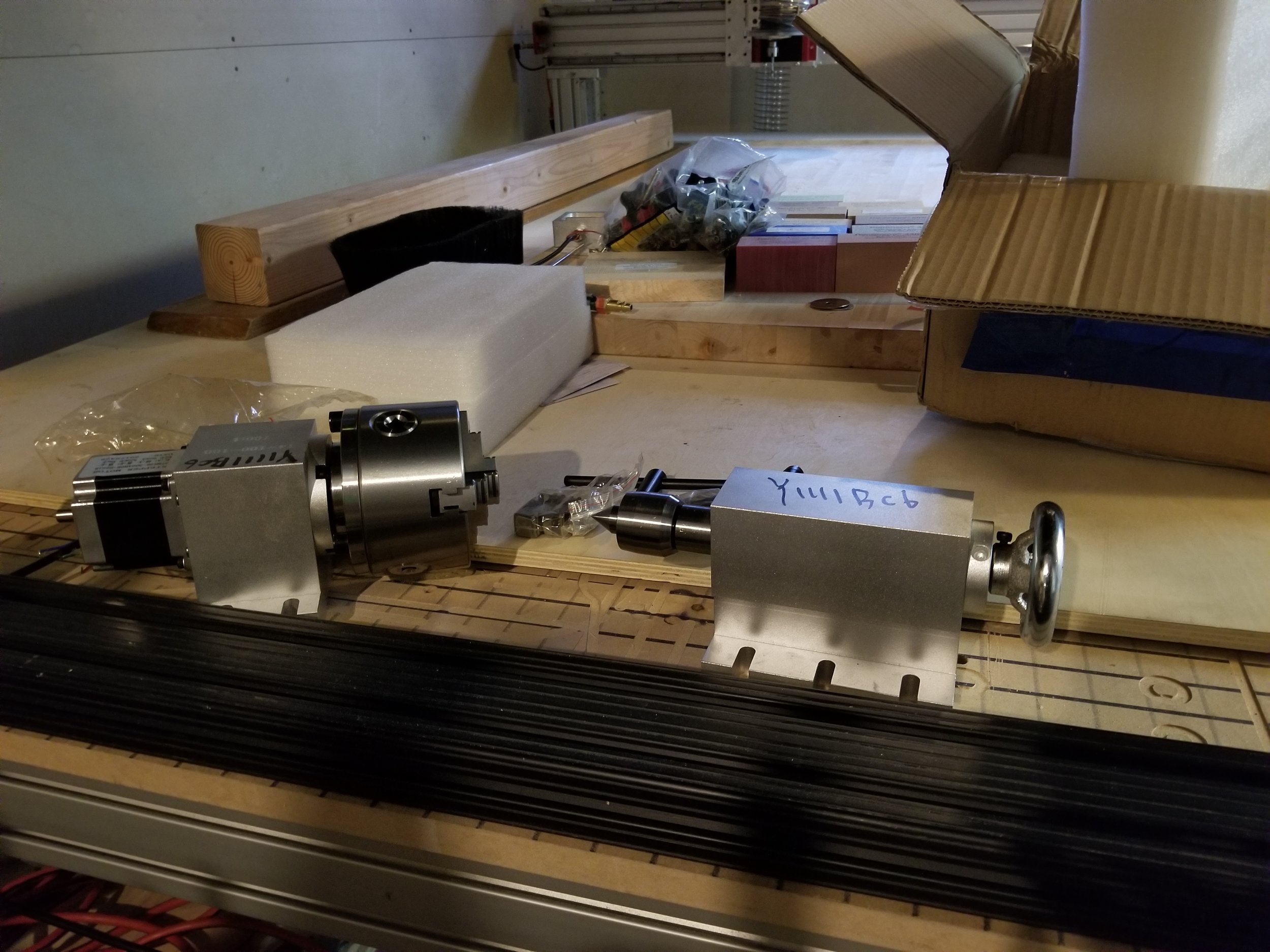

I ordered a 4th axis from AliExpress the other day. There was a sale, so I got it in hand within a week and it cost me around $400 shipped. Now that I have it, I need to figure out how in the world to use it.

This guy set his up in almost the same way that I am. I purchsed a harmonic drive version that has a gear ratio of 100:1. I believe his is 4:1. With a NEMA 34 stepper, I guess it has the force needed to hold the work. However, I am using NEMA 23 and I would like to have as high of a resolution as possible as well as the added holding strength.

I have posted on the CNCZone forums about modifying or adding simultaneous machining using a post processor for Mach3 through Fusion360. I recevied a reply from one person stating that continuous machining is coming to Fusion soon. I have no real understanding of the differences yet. I need to read up on those details. He said that I need to use a hack to get it working in a way that wraps the plane around the axis. The first person I linked to has his set up in a way that he basically does one plane and then rotates to the next. I am looking for the ability to machine around the axis while turning. I am sure that I can get this capability form something. I would rather not hack it together.

I will be working on this until I have have it functioning properly. Then I can make table legs, ornate ones.

Leave a comment