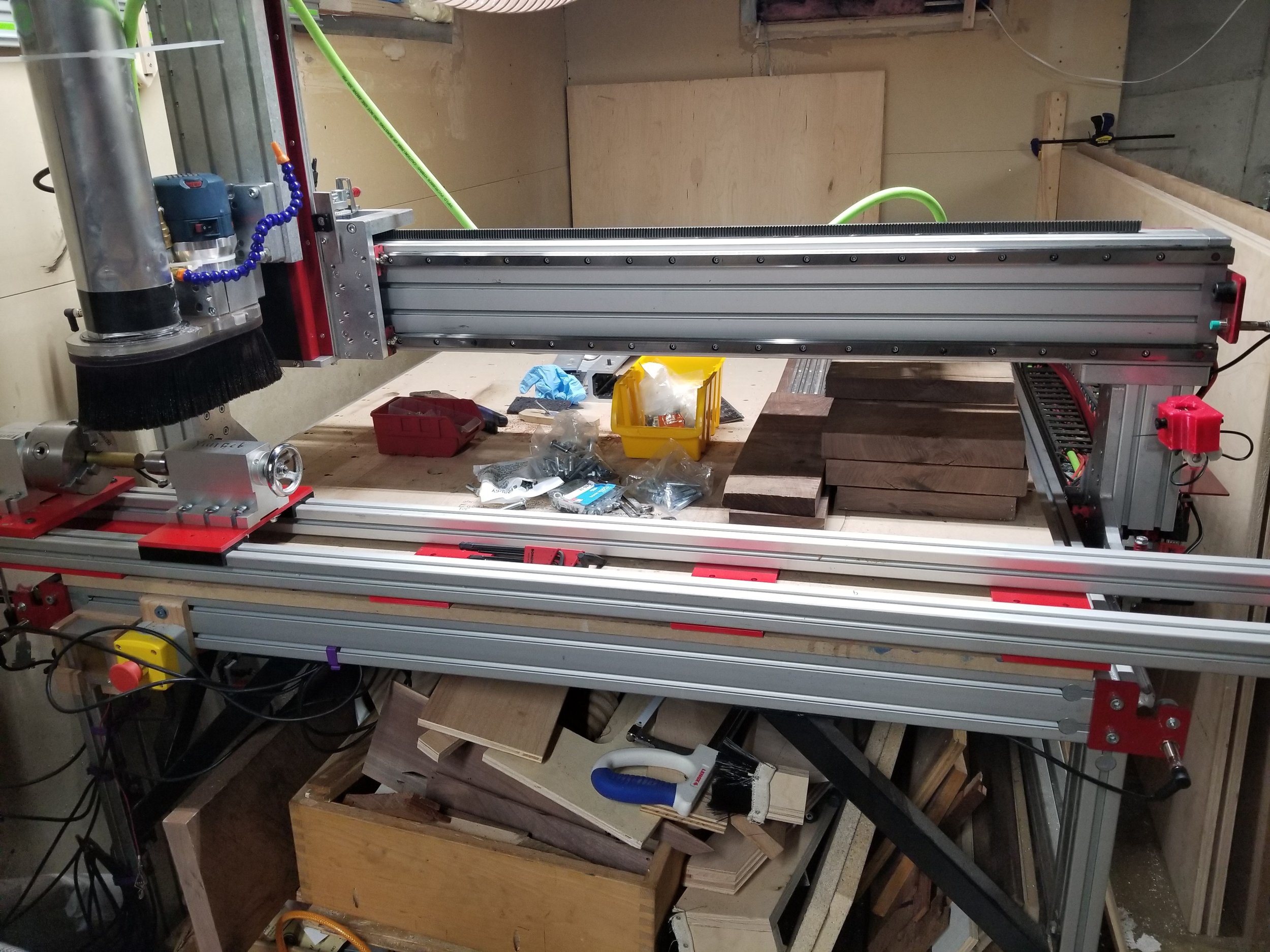

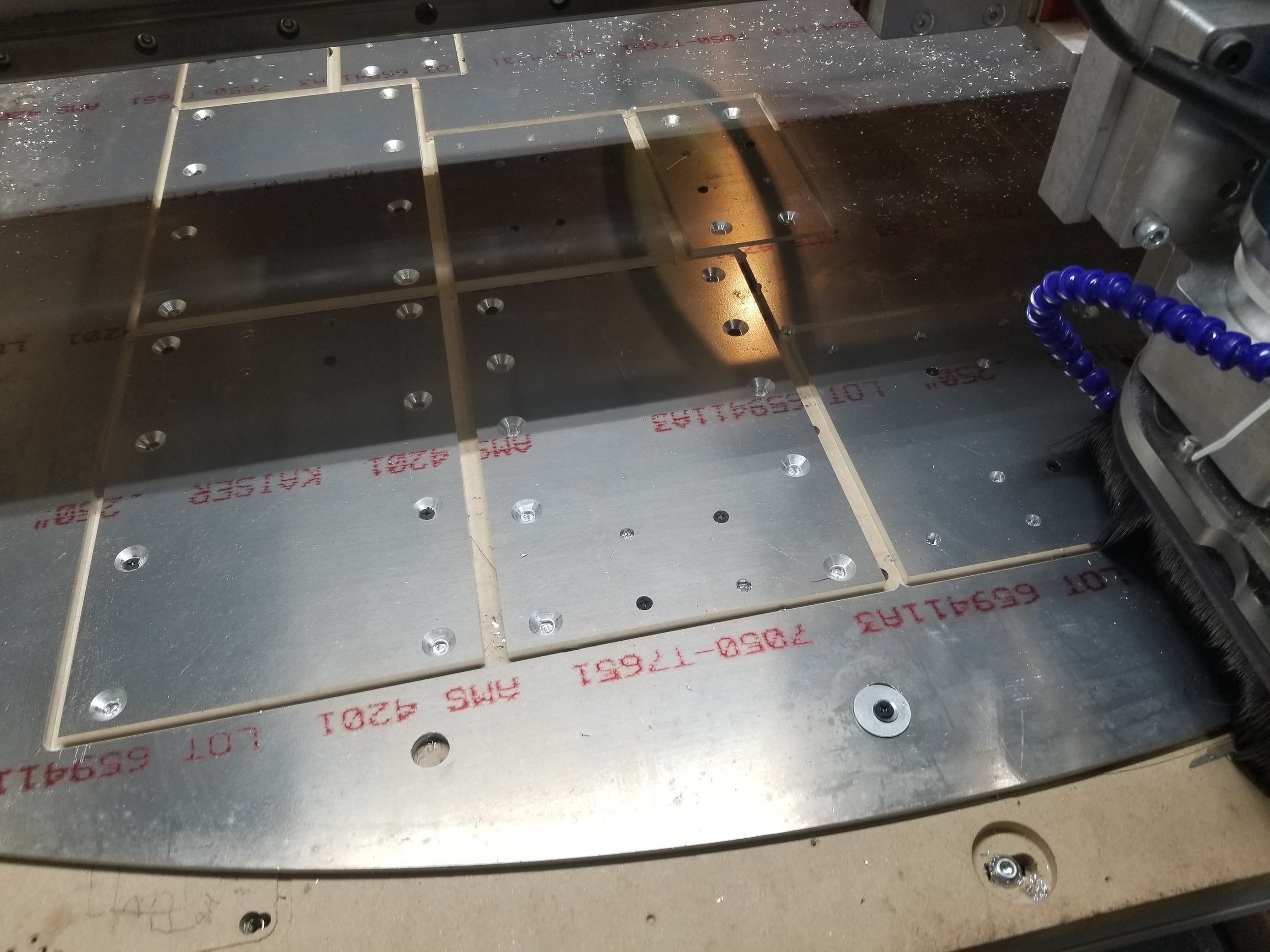

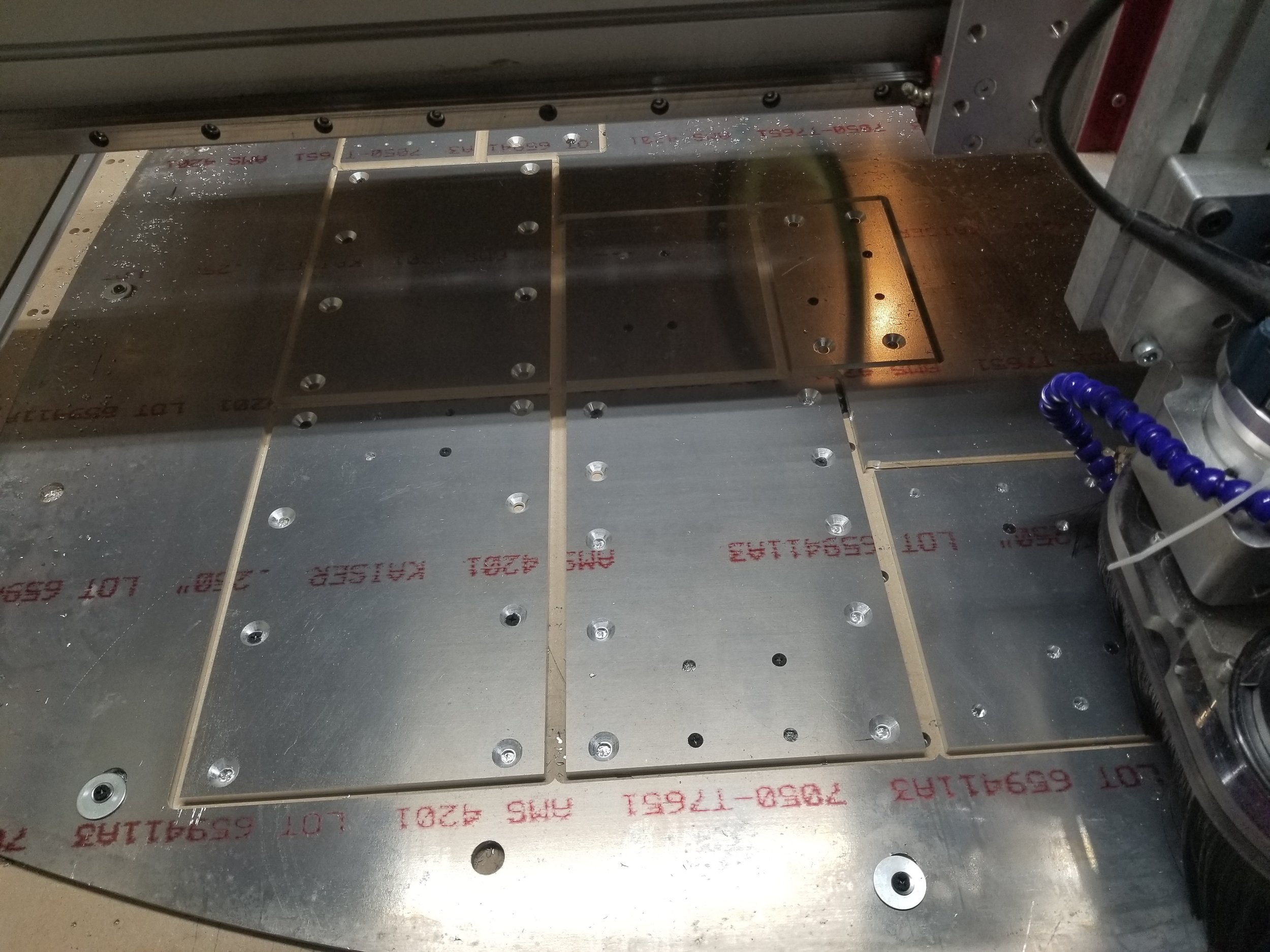

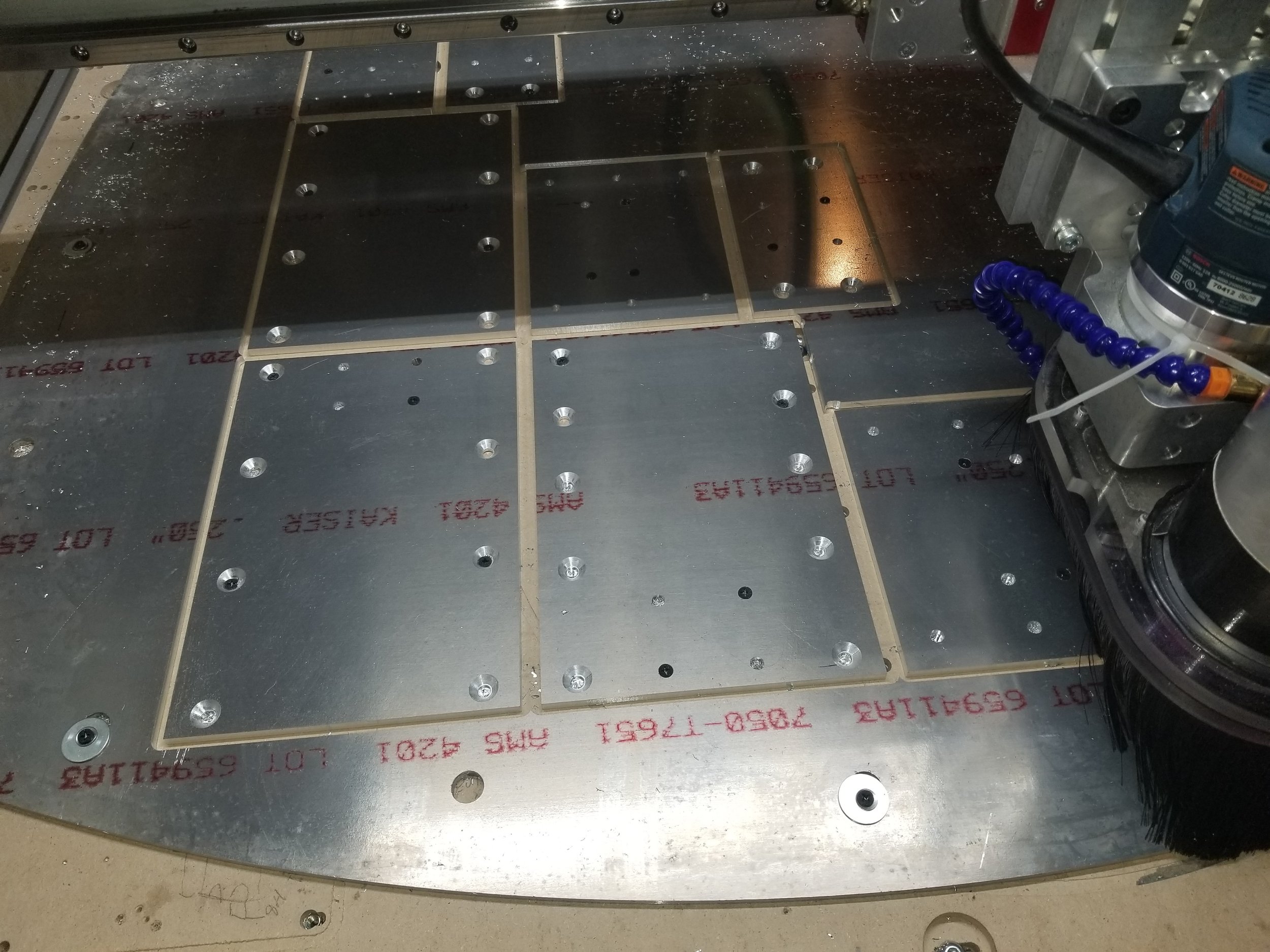

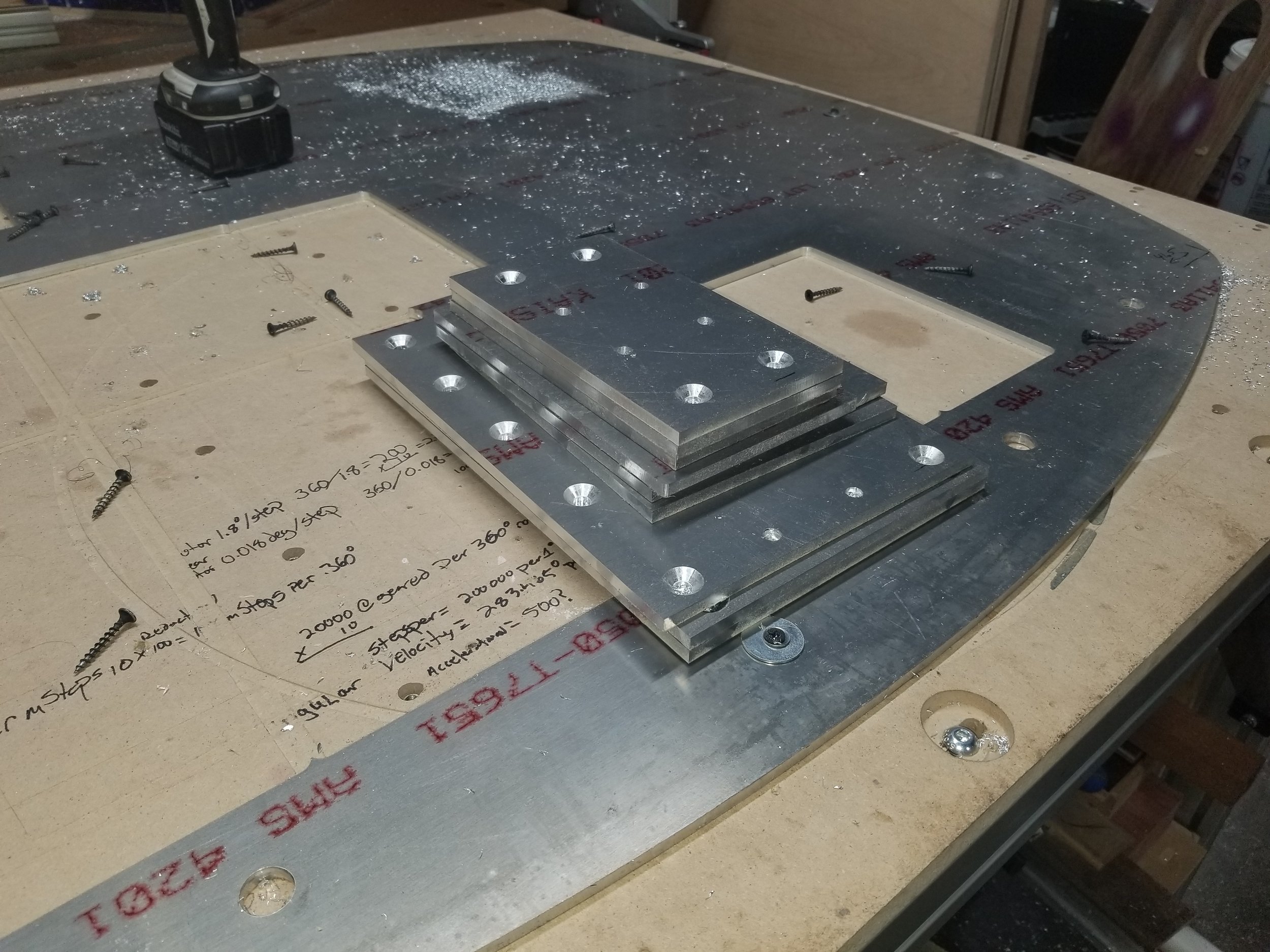

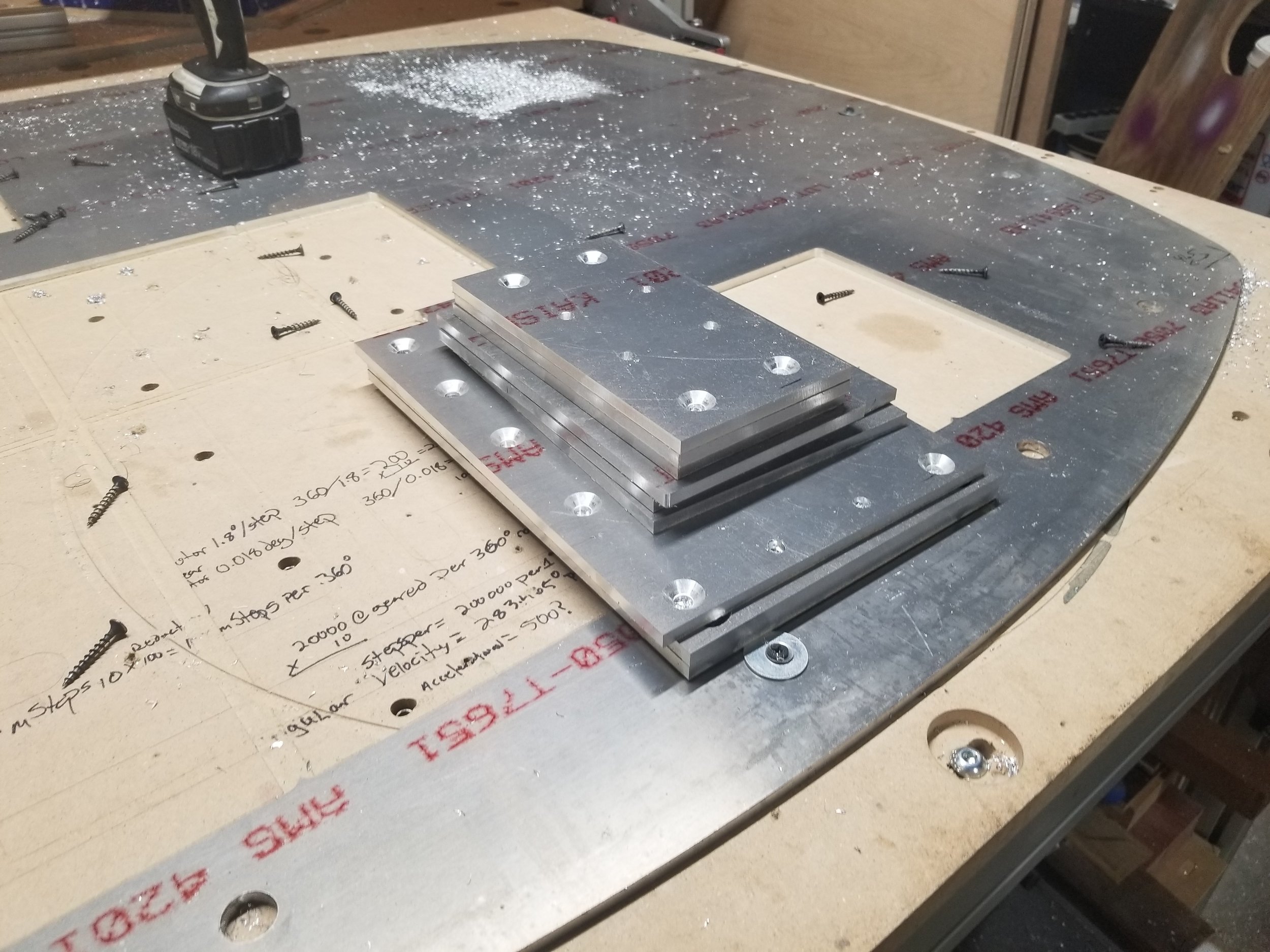

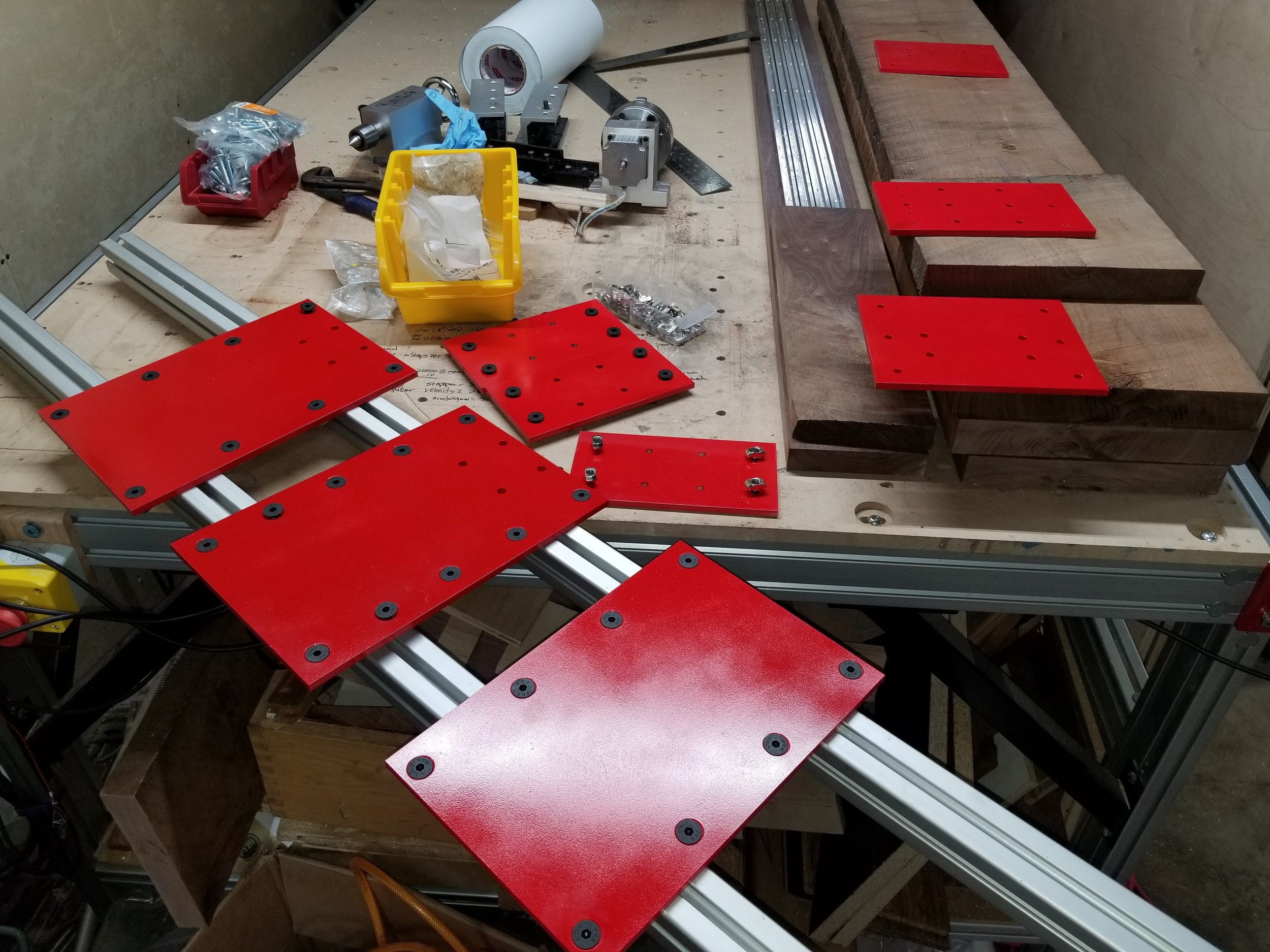

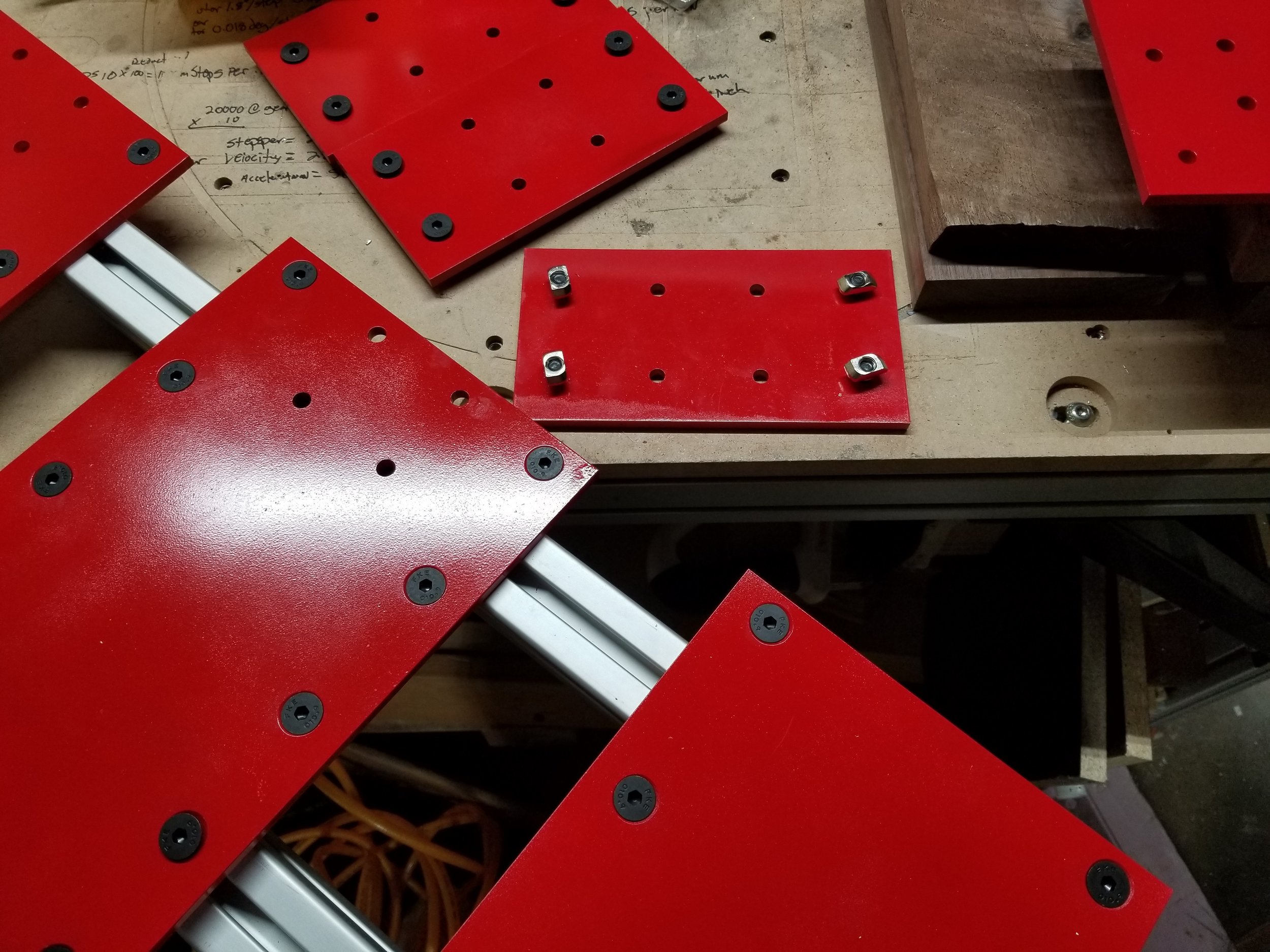

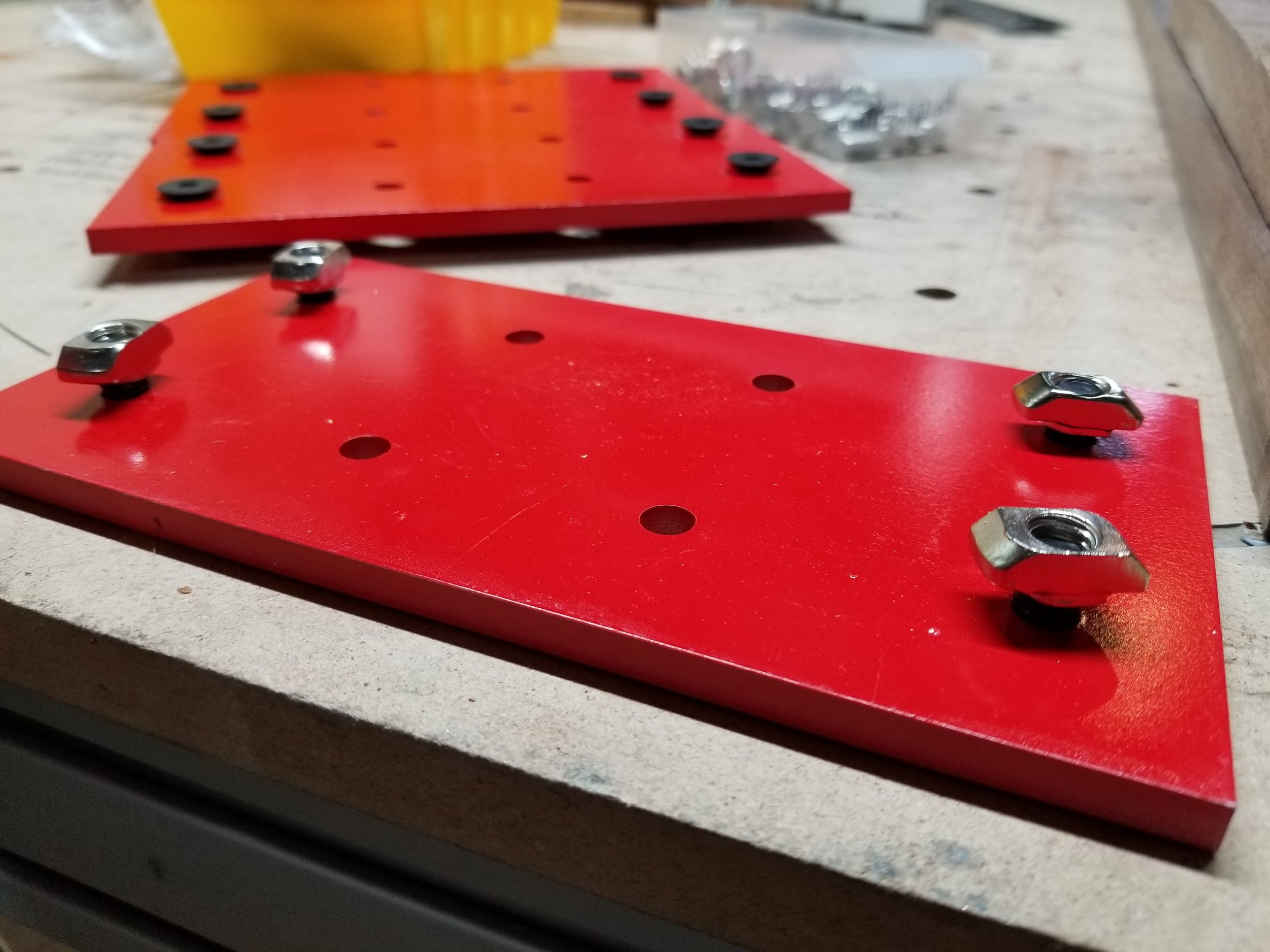

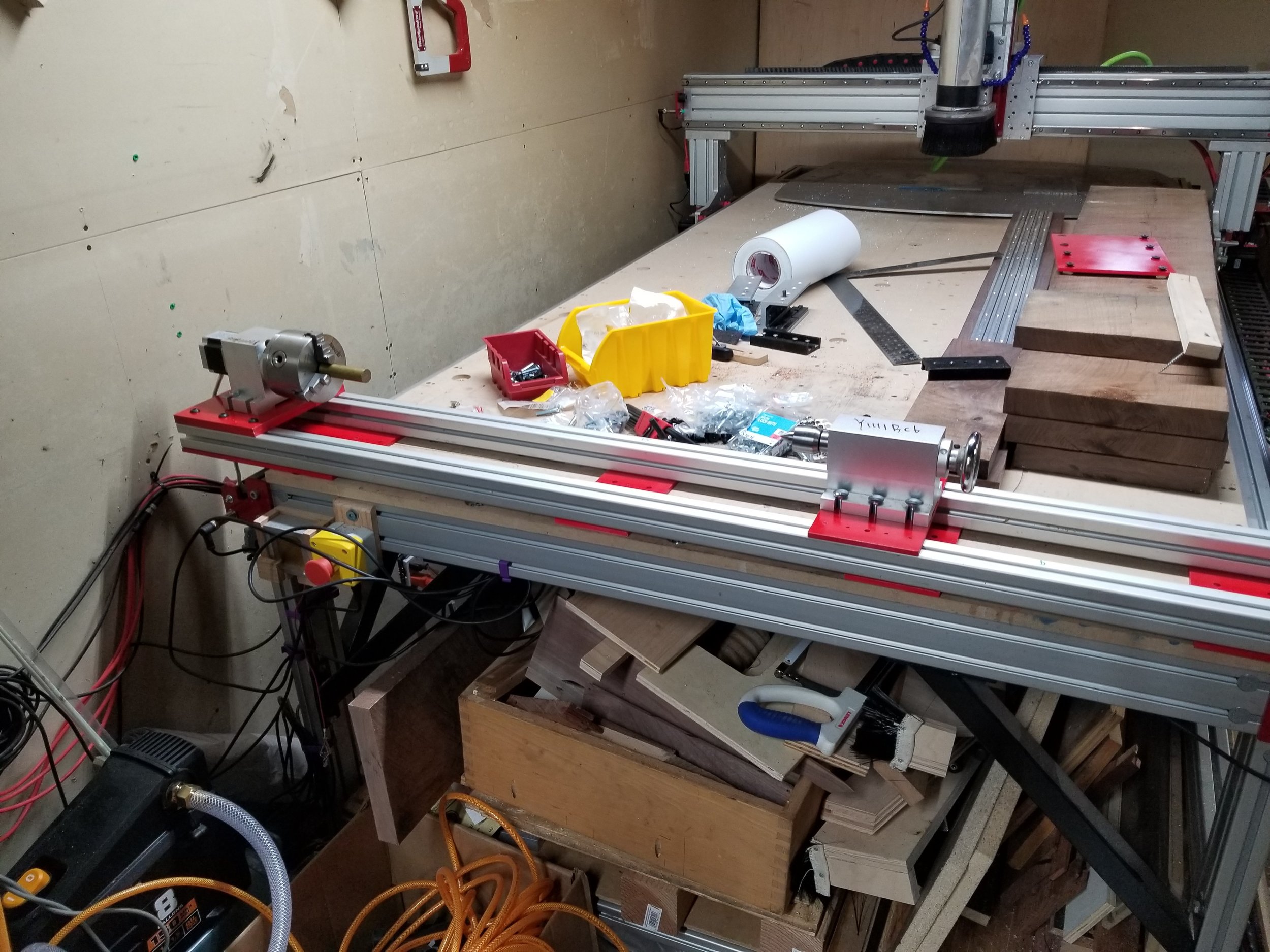

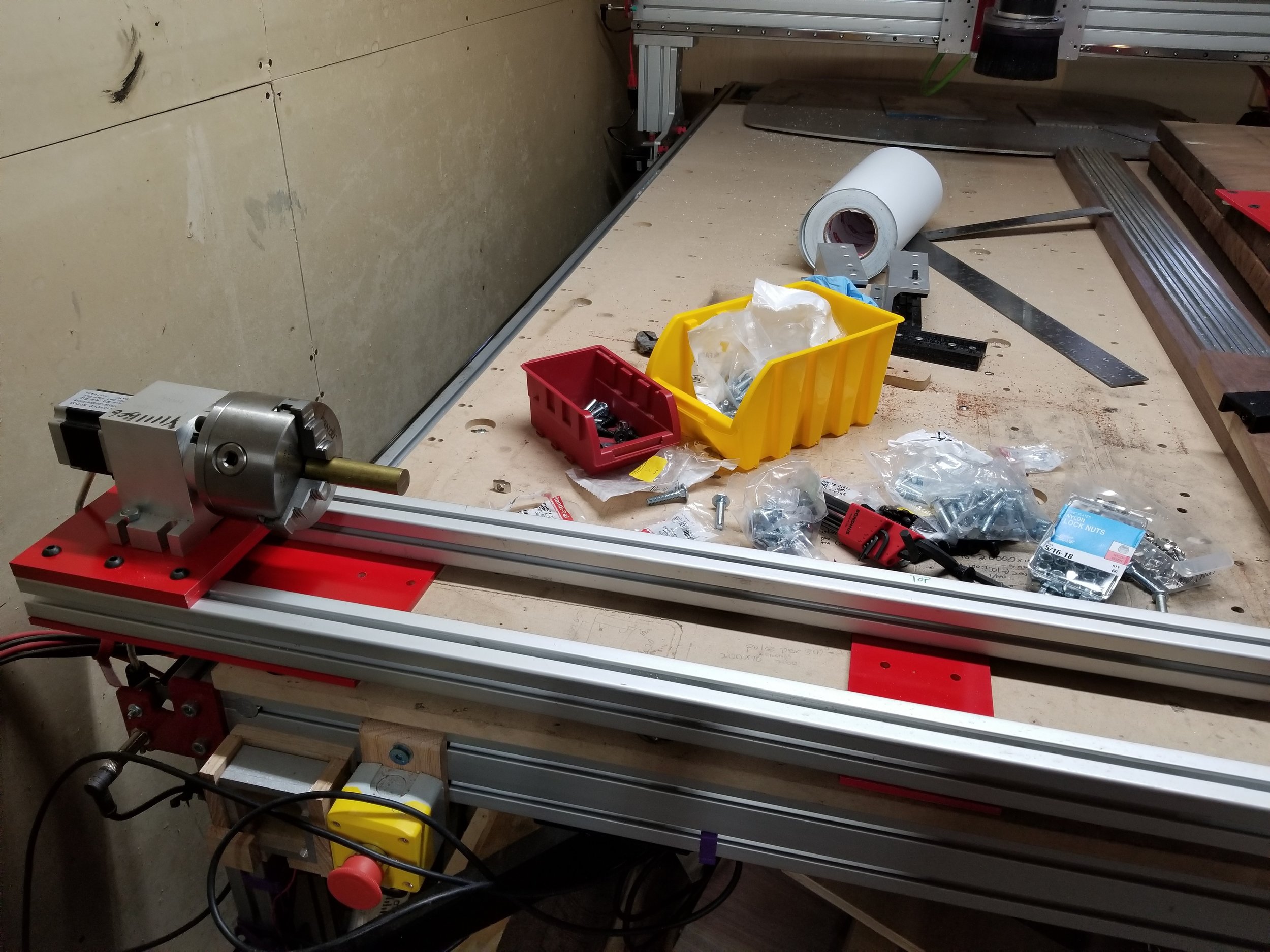

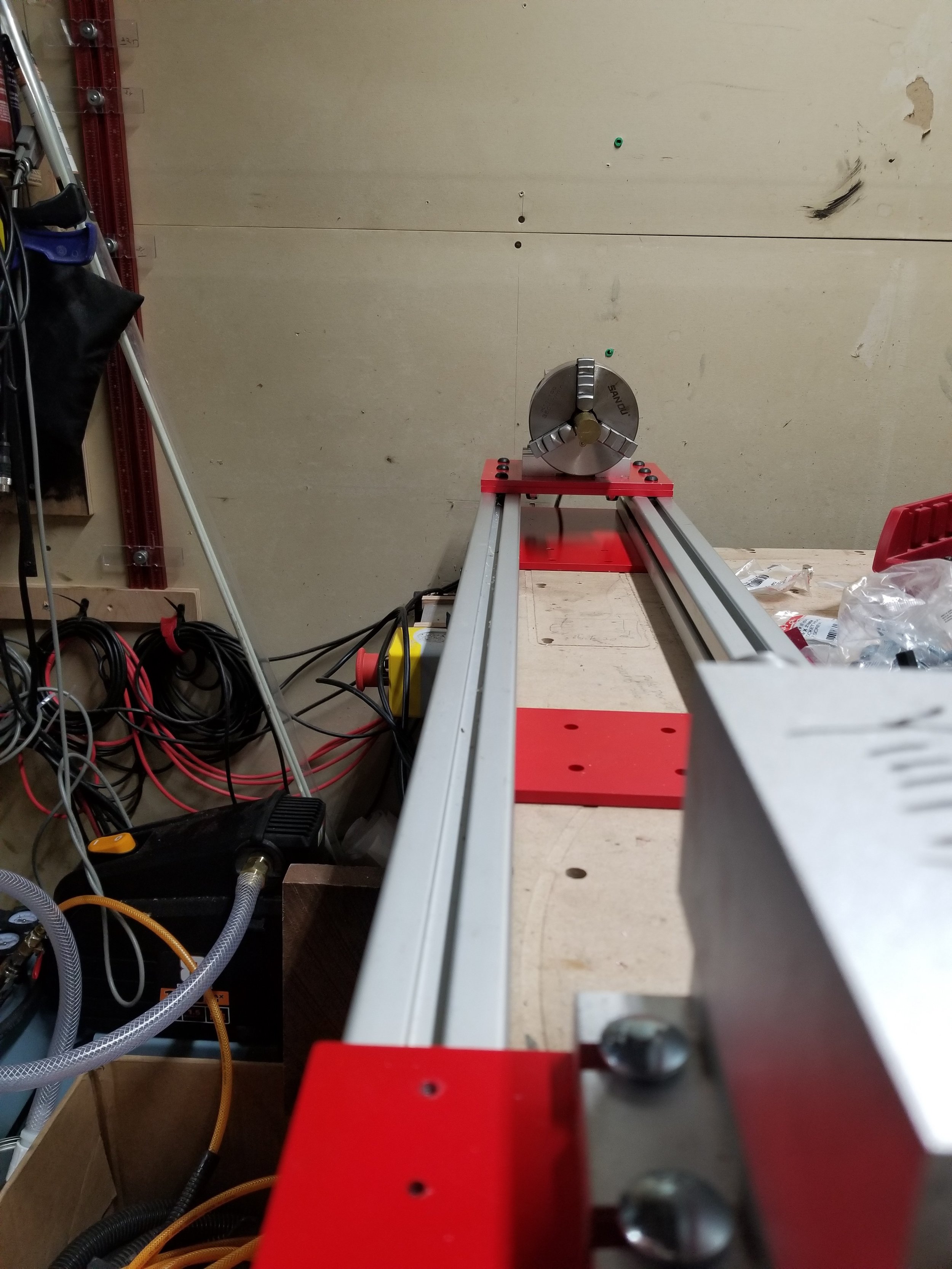

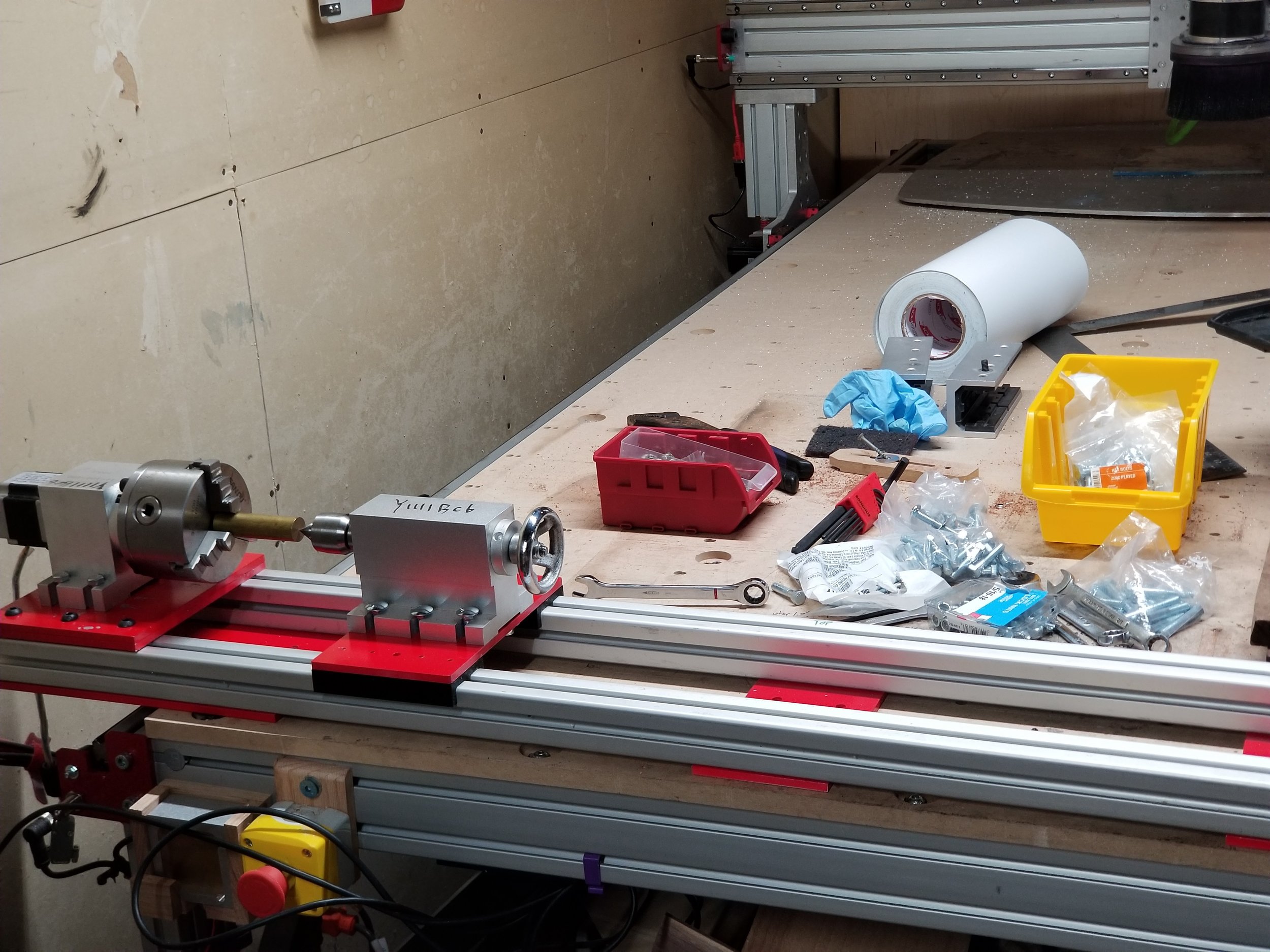

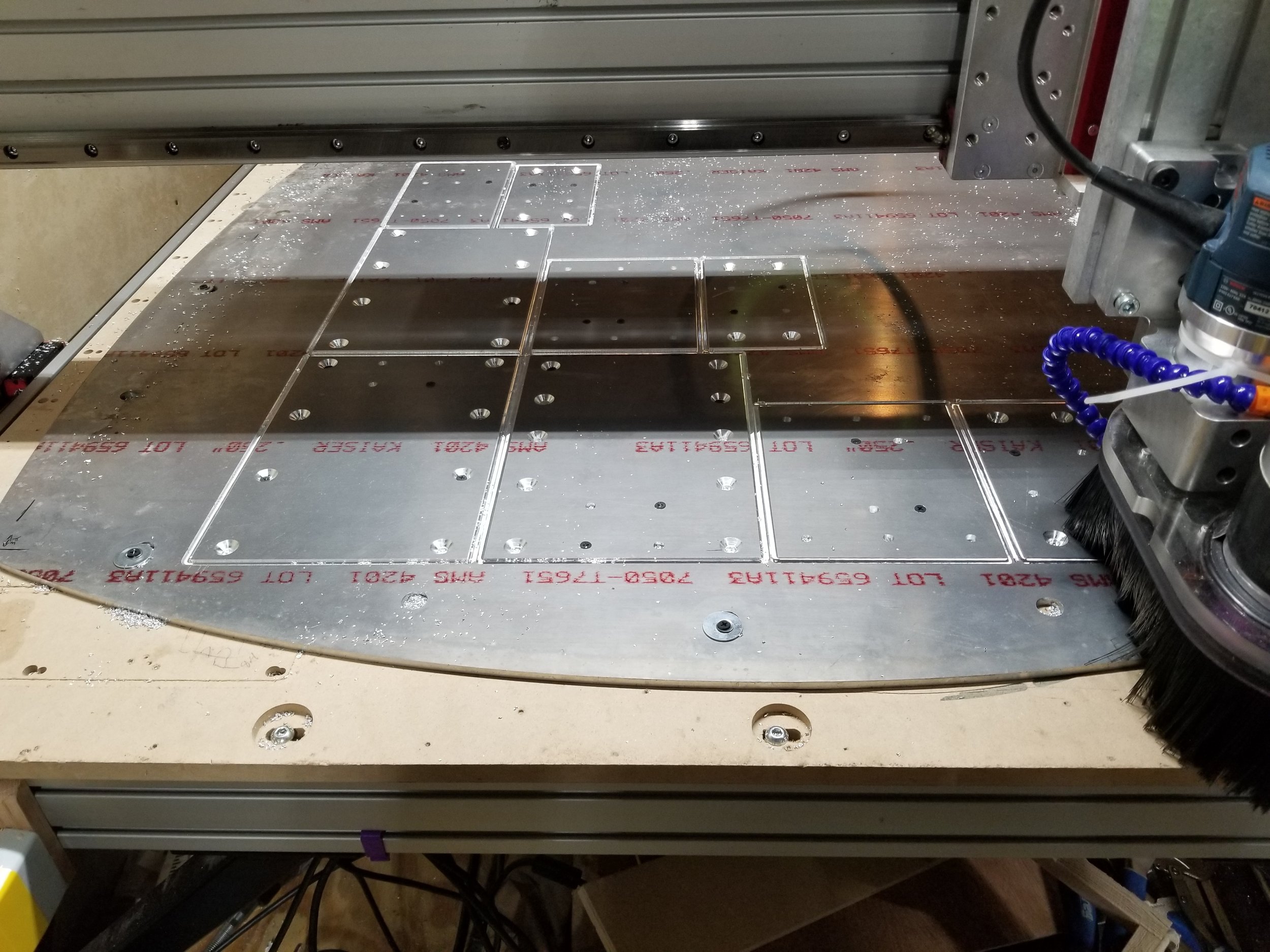

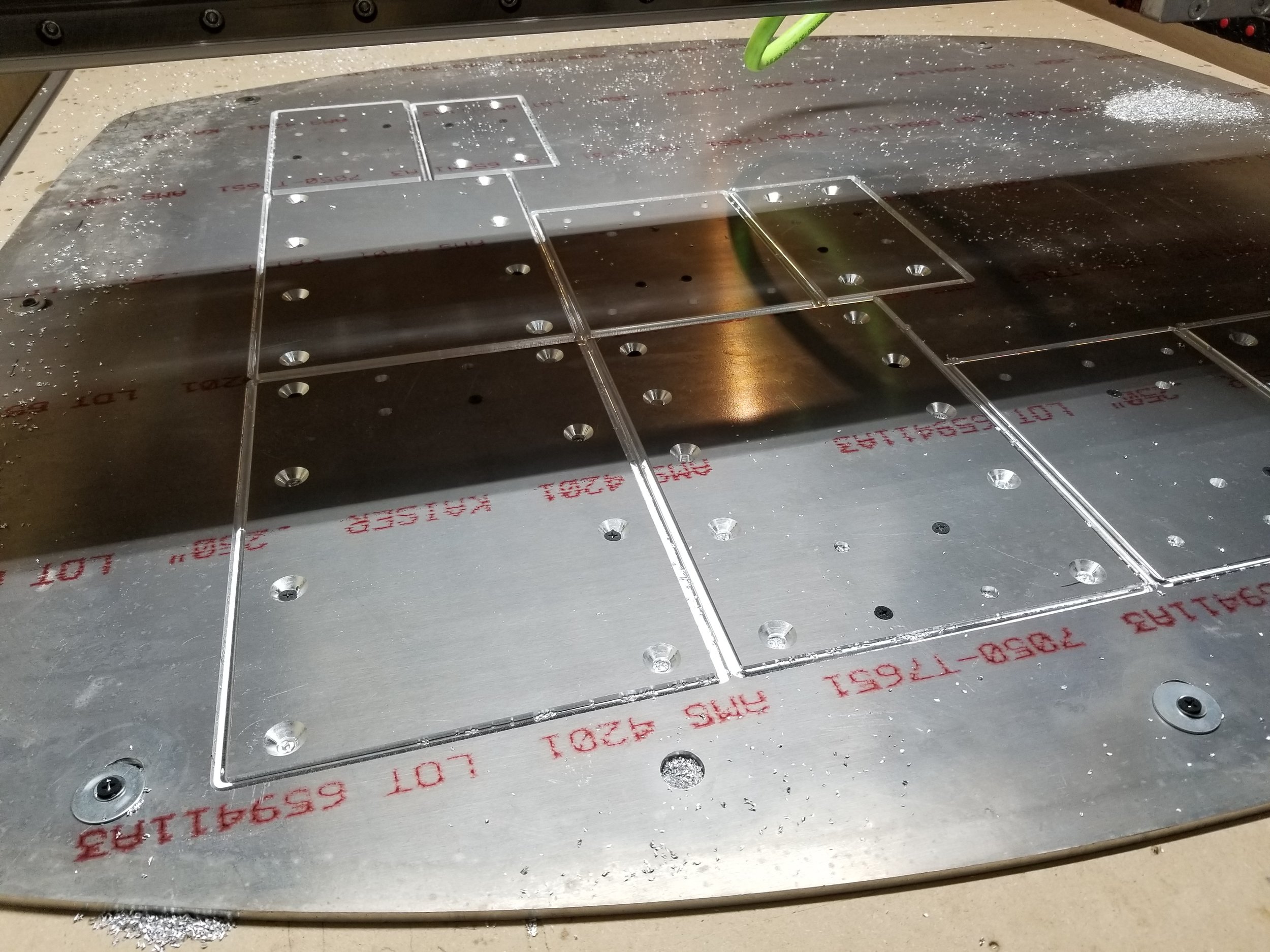

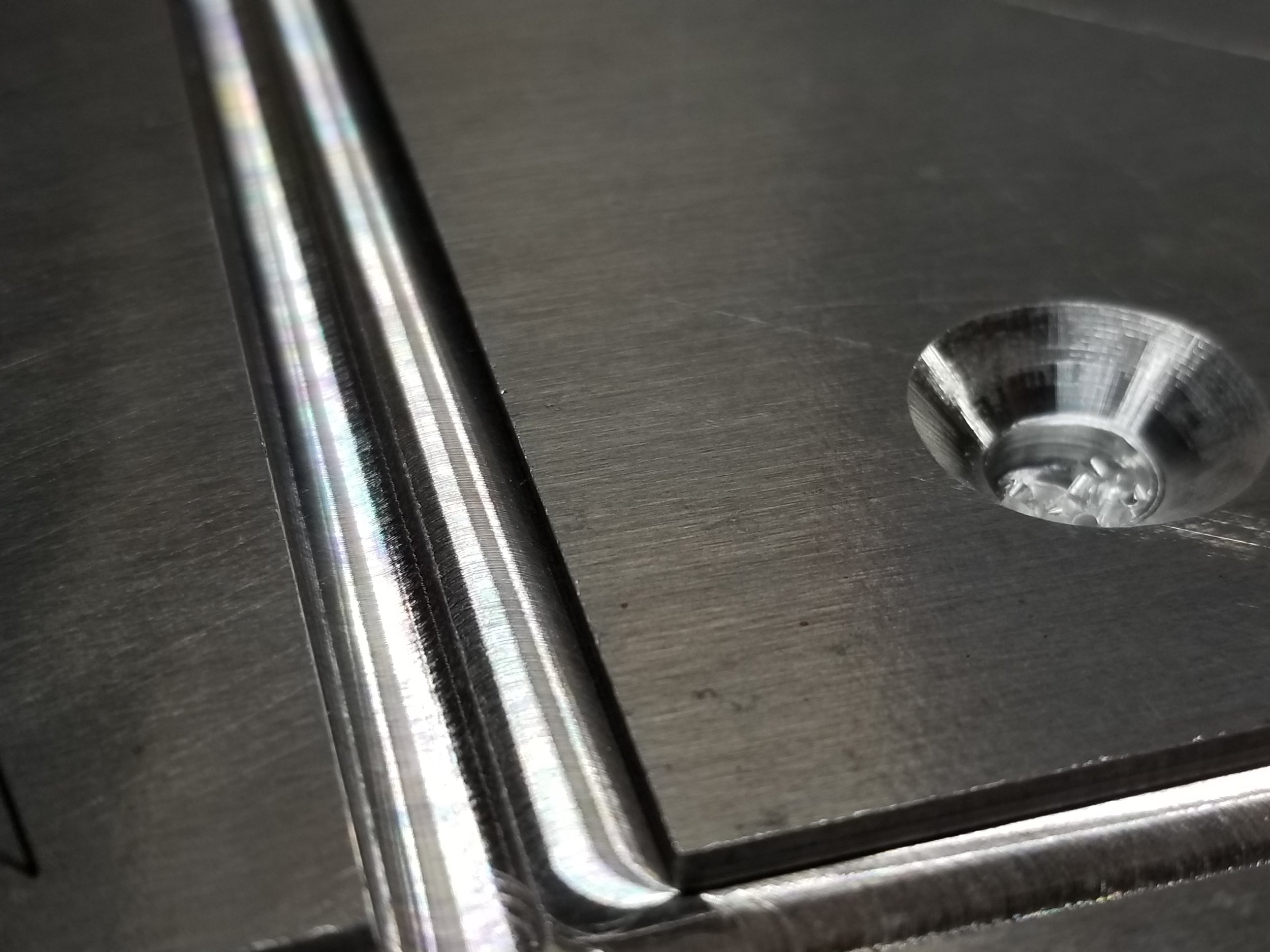

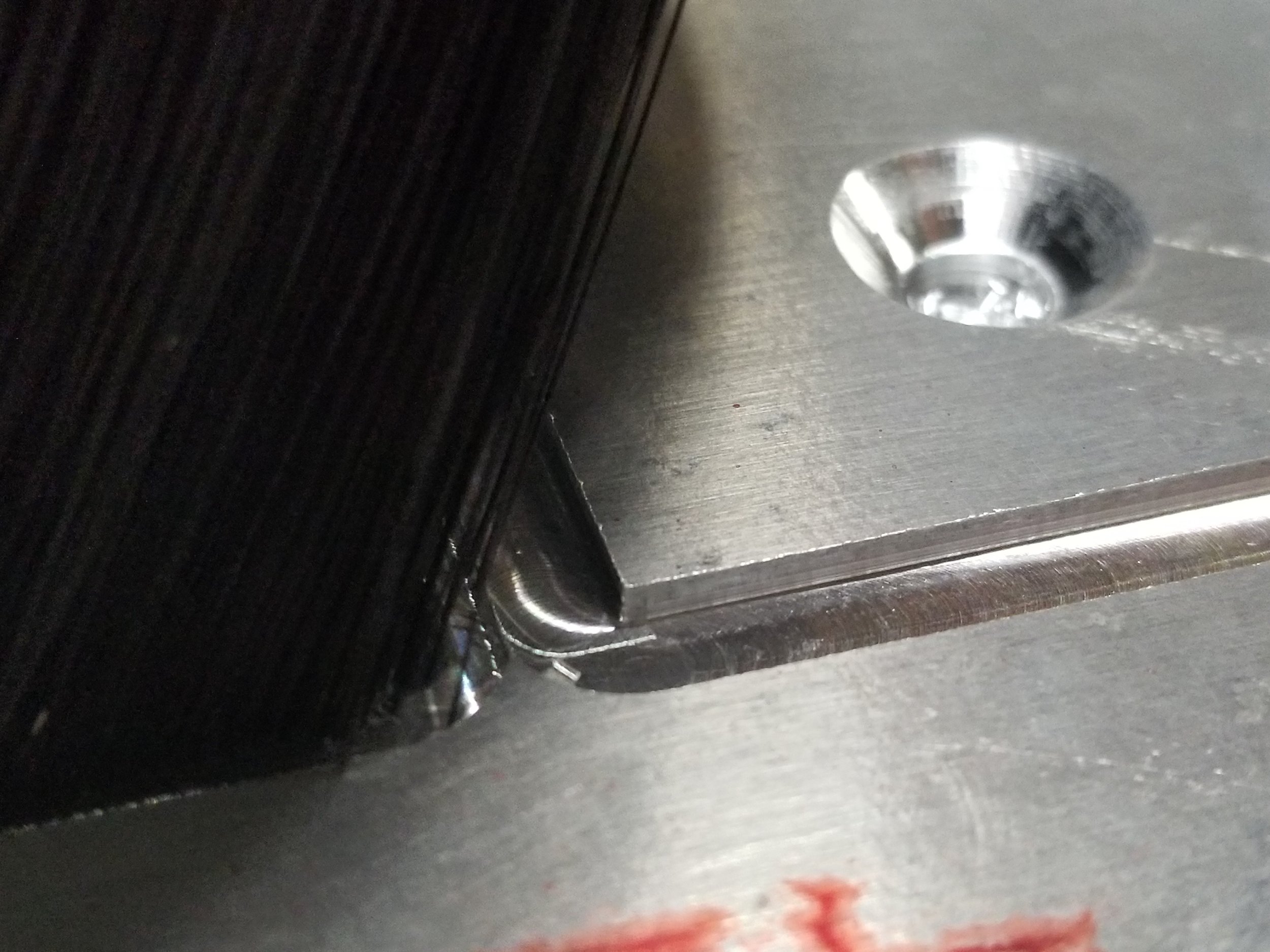

I have cut all the aluminum plates. Spray painted them and mounted them to the extrusion.

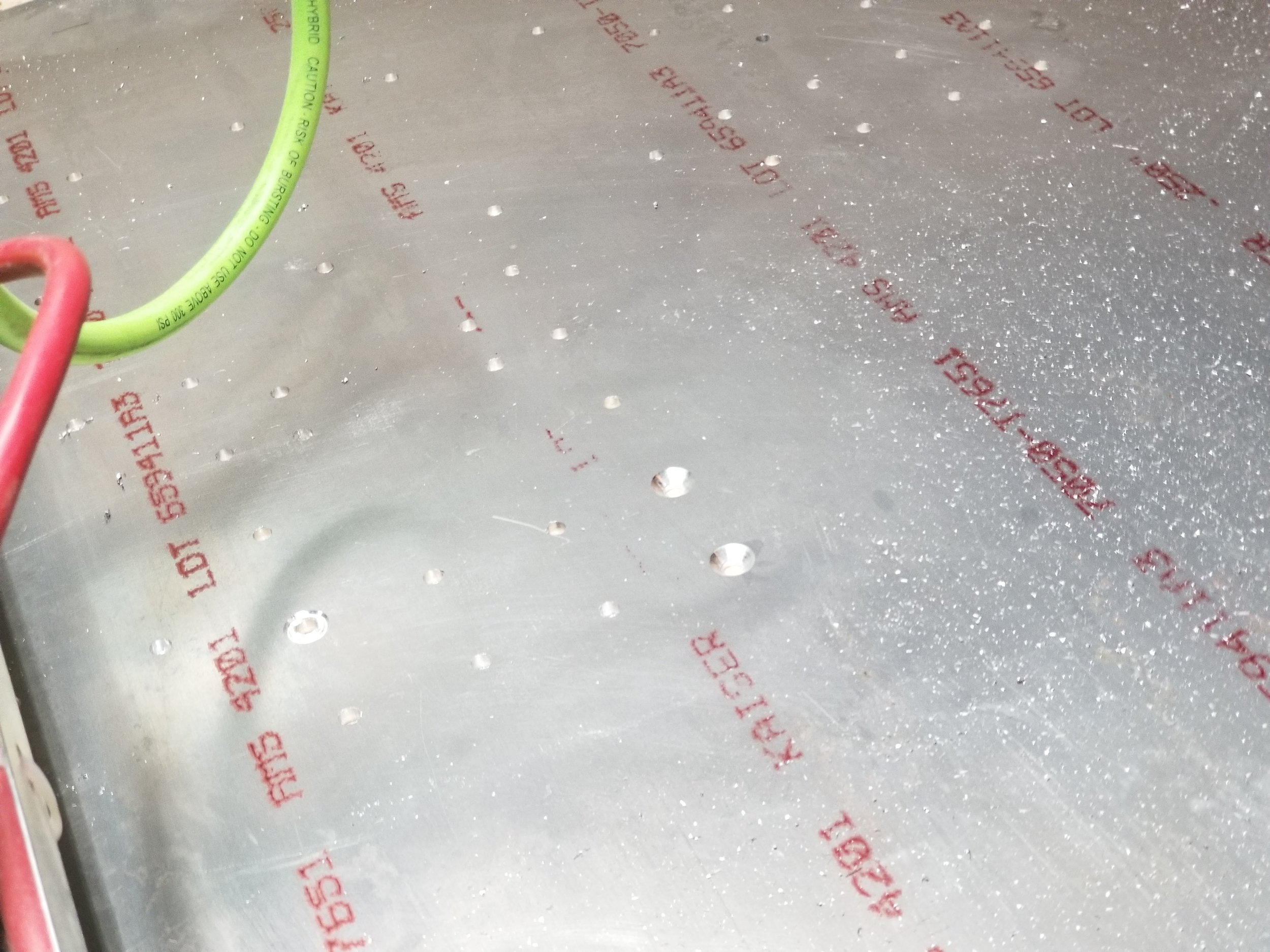

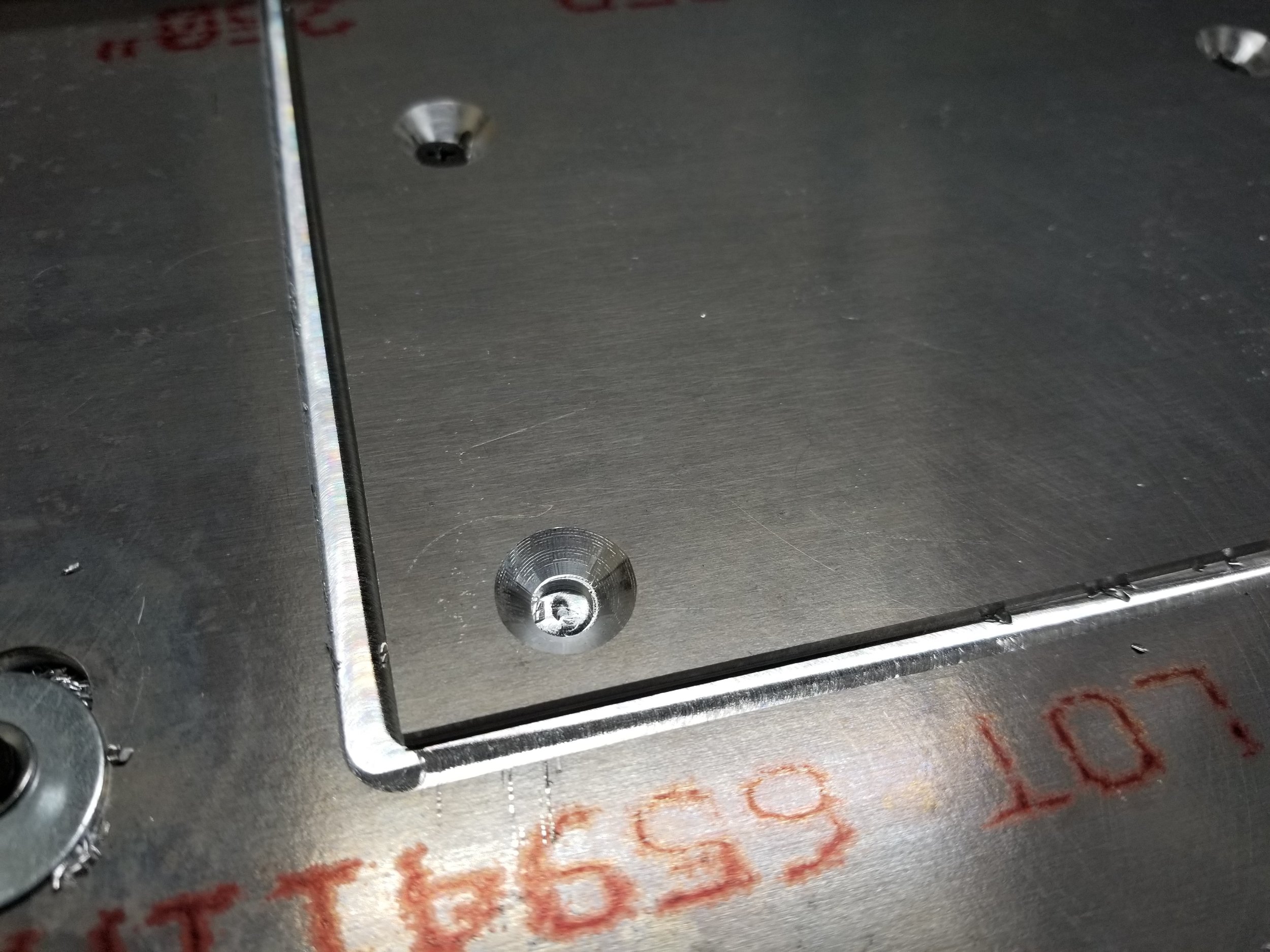

The aluminum was a little challenging for me to cut accurately with the CNC. Dealing with the fact that I do not have a spindle and the speeds needed to cut well causing deflection, it still came out well. I had to fudge some things to get the bolt holes round. I decided to drill them after clearing the area well enough with the CNC.

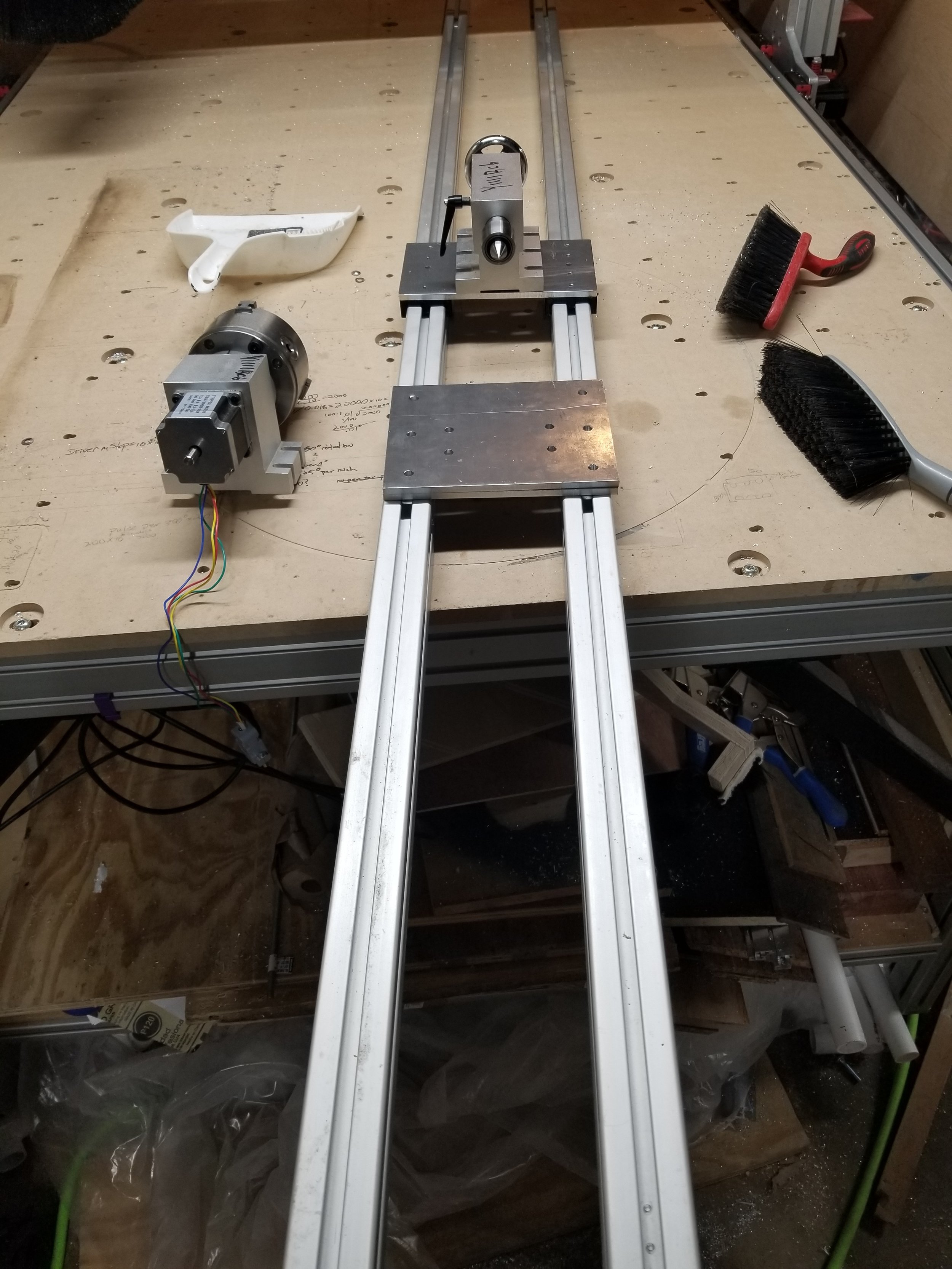

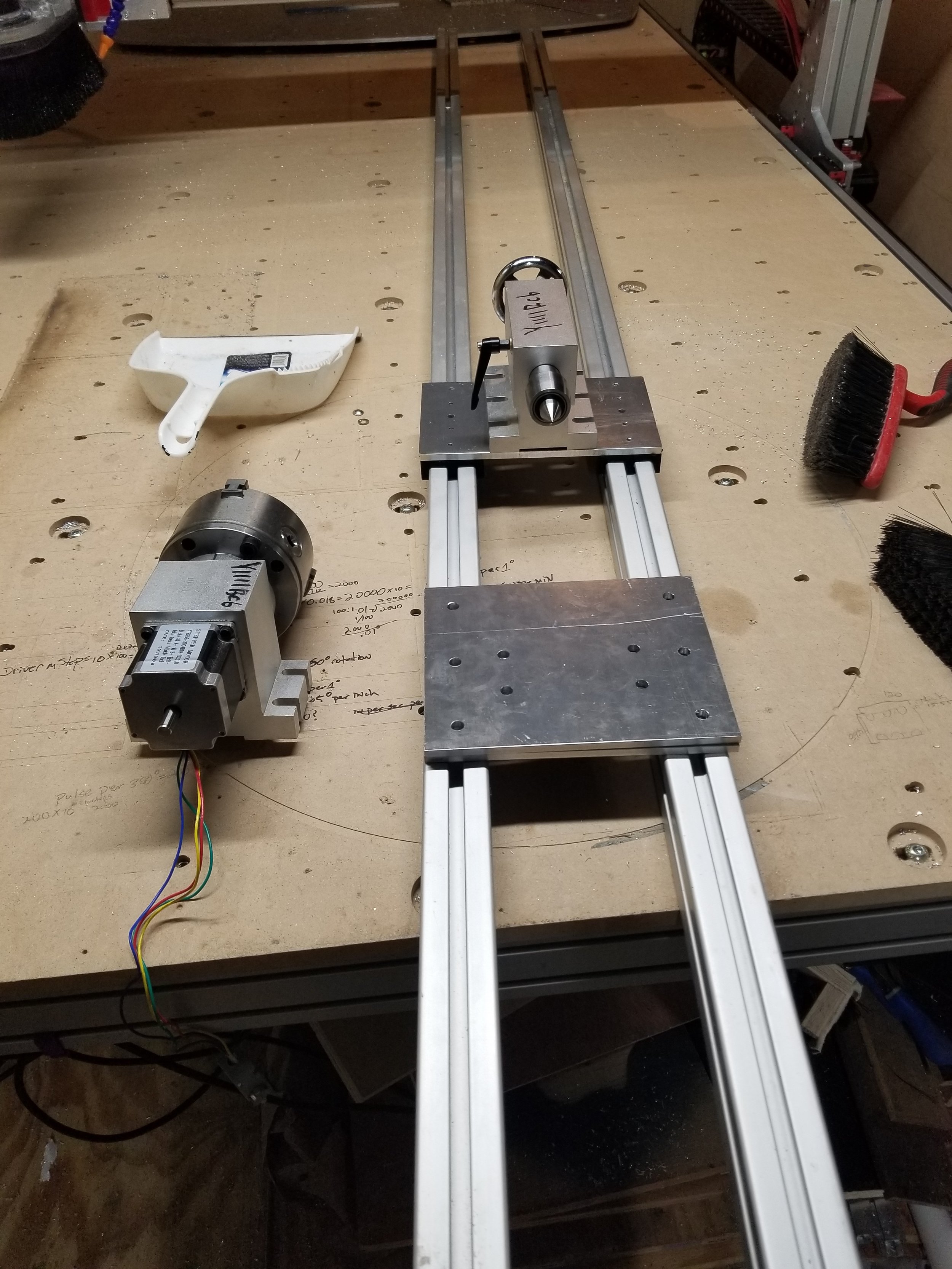

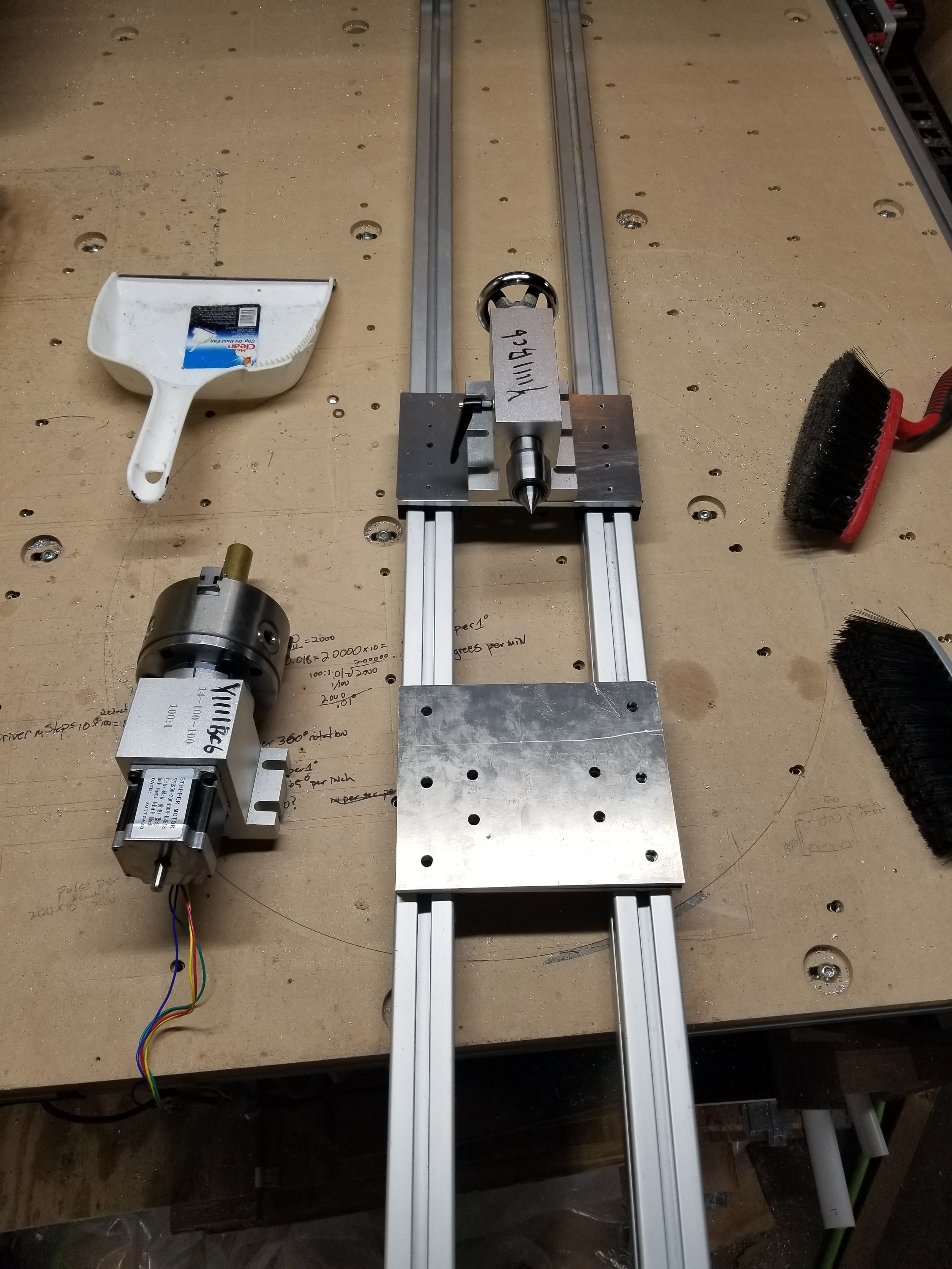

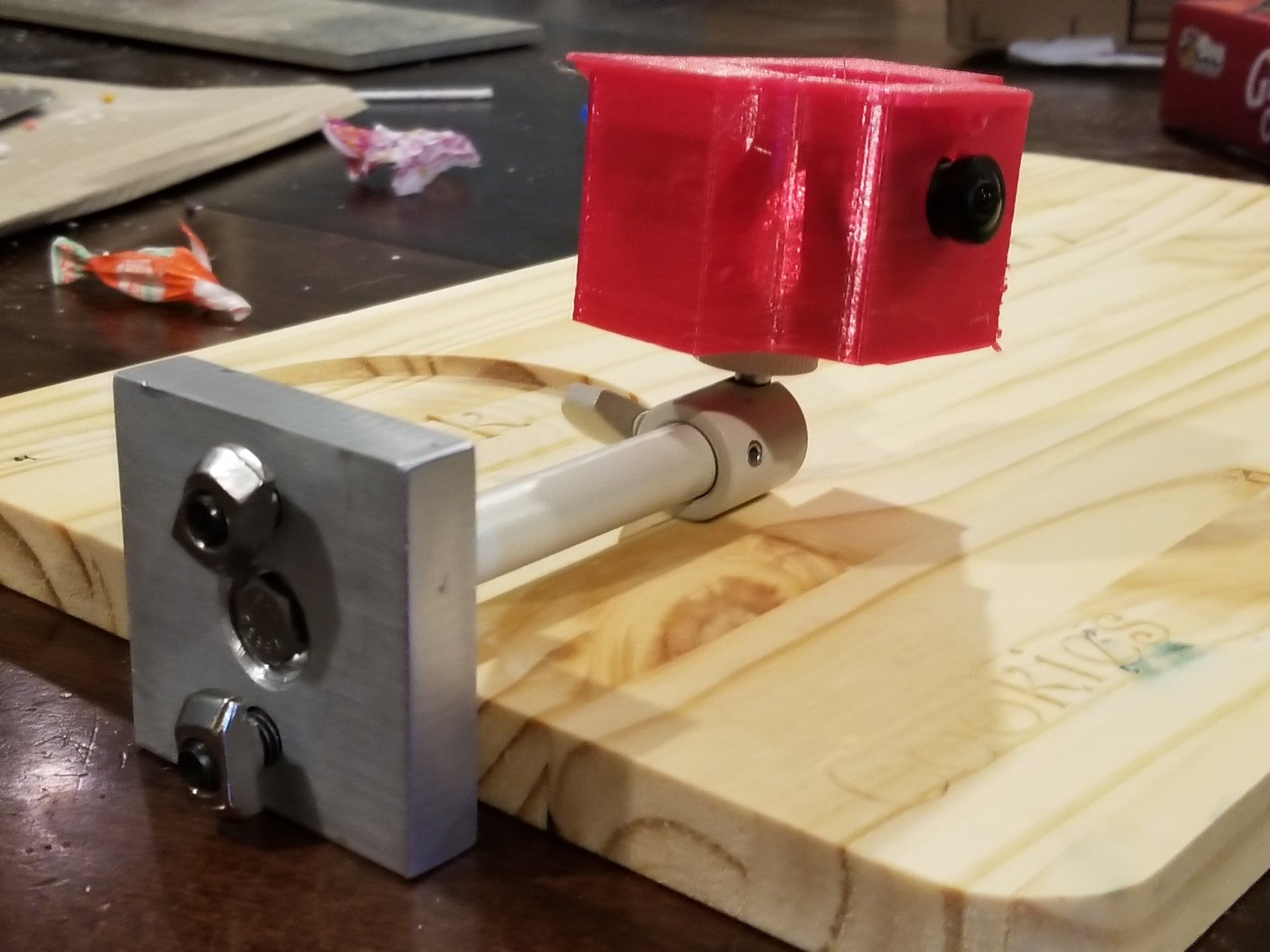

Next, I need to design the mounting brackets so that I can reference end stop positions while the axis is mounted. I want it on there semi permanent, so the mount is a must.

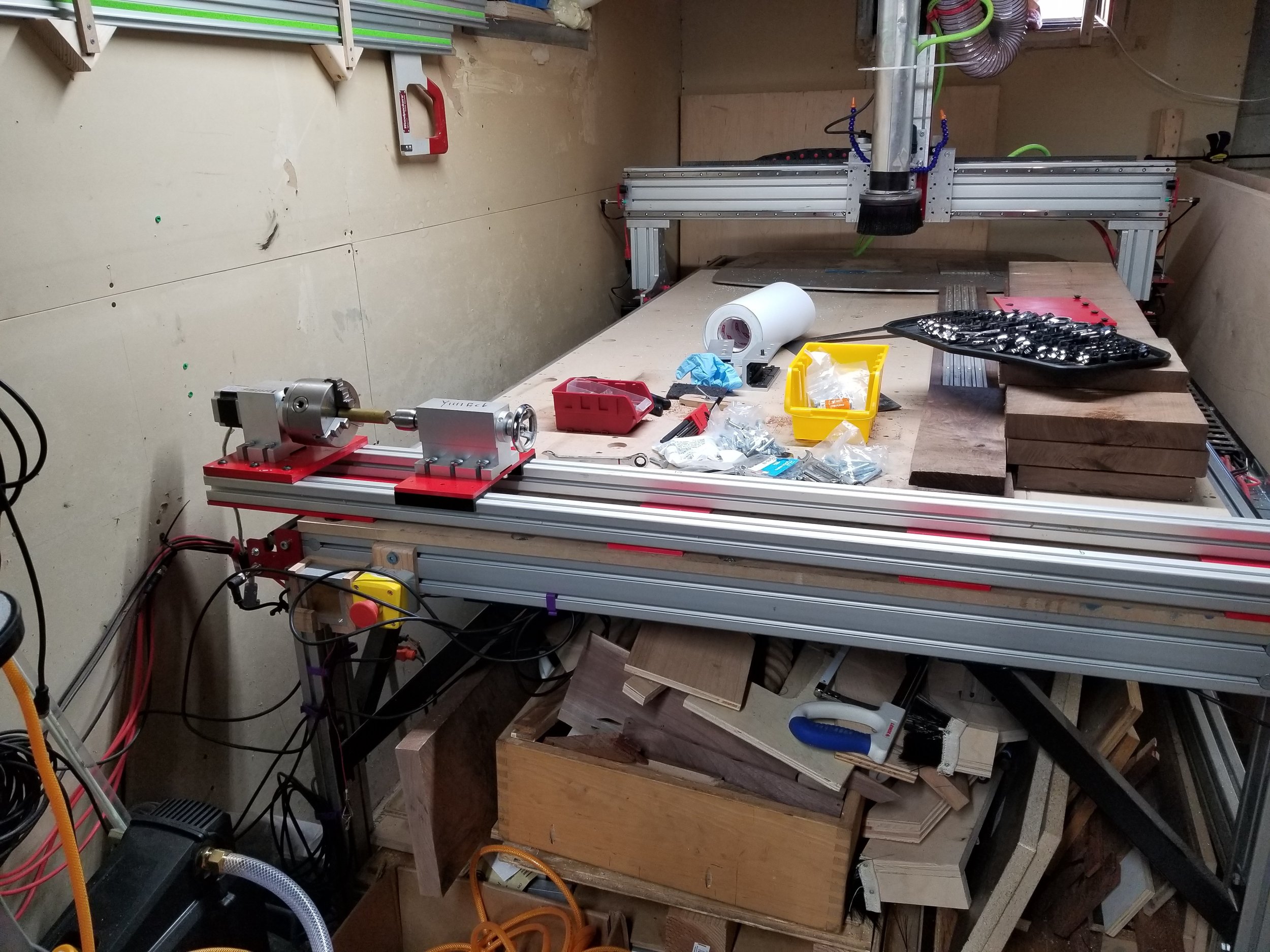

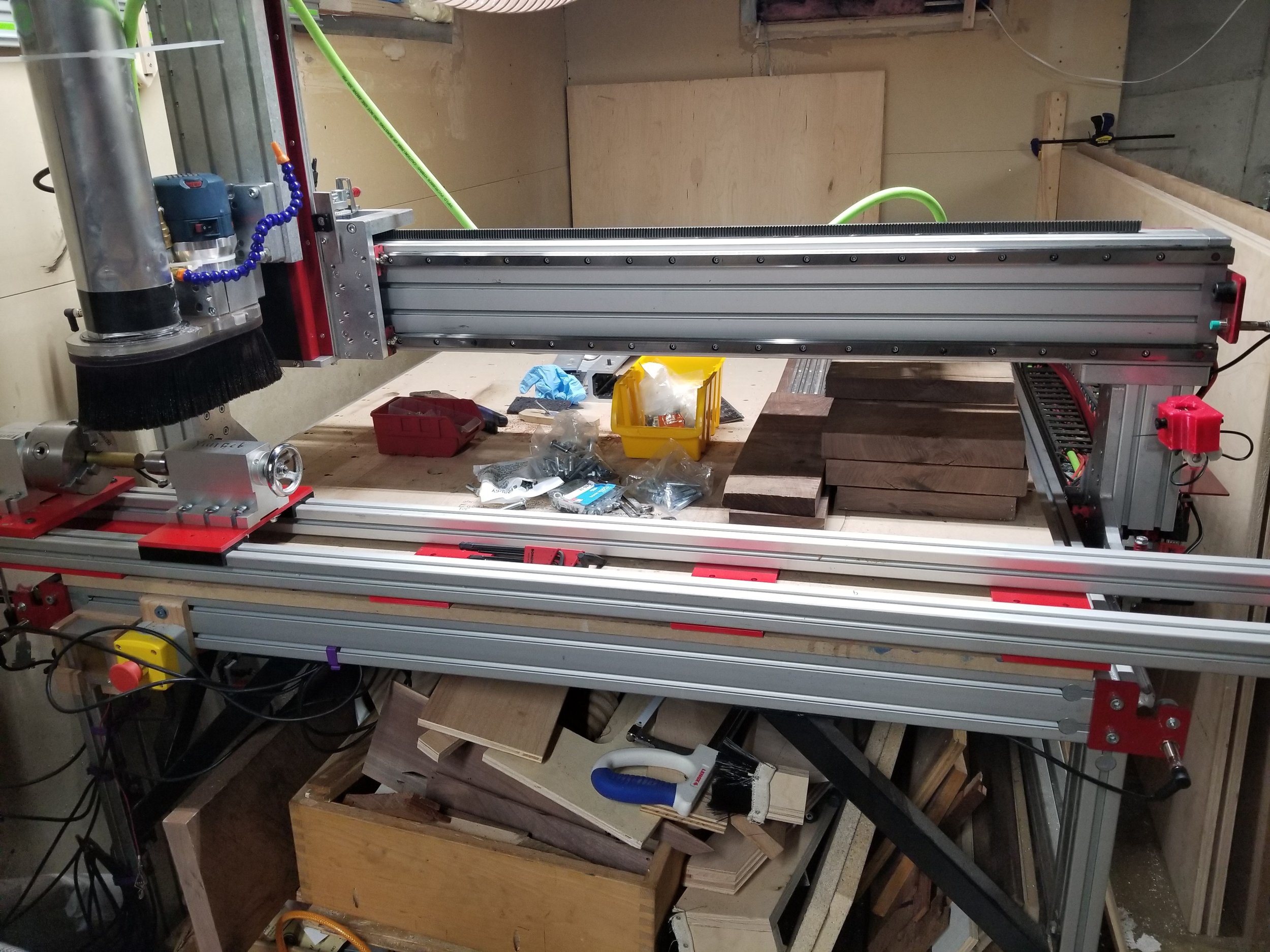

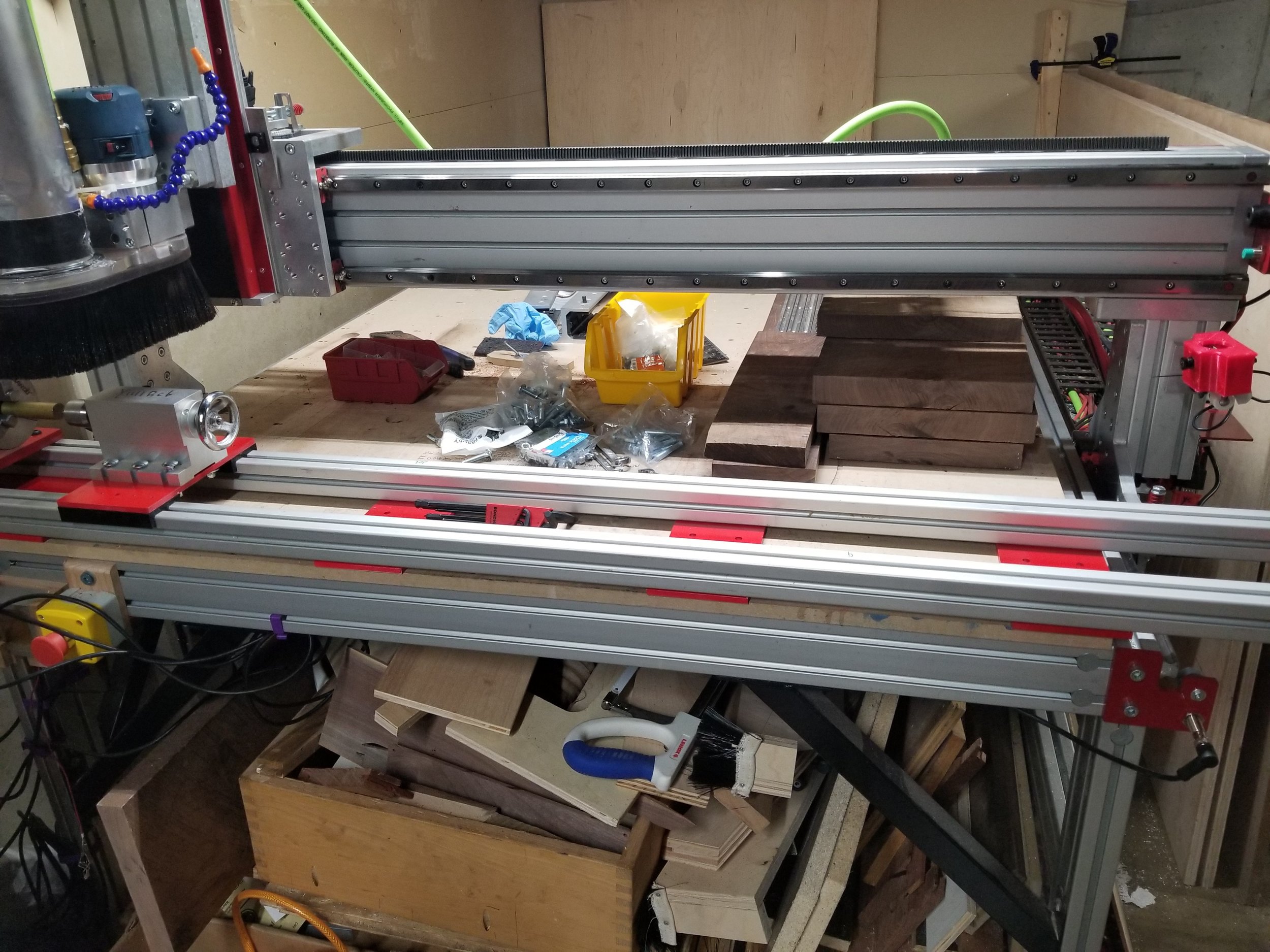

I redid my spoilboard while I was waiting for some boring bits to come in. Now I have everything ready to move forward.

Pretty annoyed by how much time a timelapse takes to post process and gather. GoPro, for how well they work, sucks. I have very little control remotely and the processing is all offline. I built a Raspberry pi timelapse camera setup that is about the size of a normal webcam. It has a web server interface and timelapse is processed onboard. Afterword, I can press a buttoin that runs a script to upload to google drive and then erase the original files. Cost = $60. Whats up GoPro? Make stuff easier to do. If I can do it in an afternoon and design a housing as well as print it, you can to.

You can see the camera on the right hand side mounted to the gantry.

Leave a comment