I do not know if it is an actual problem to solve, but I also do not want to have to replace the linear bearings on my gantry until absolutely necessary. I know they have wipers on them, but small amounts of anything could make it inside of them. At least I think so.

Pretty dirty

To make it easier to clean the areas off and protect the bearings, I looked into all the options I could think of. There were not any options available that were not custom or prohibitively expensive. Instead I purchased a bunch of outdoor material from Fabric Wholesale Direct. The 5 yards of fabric was $36.69 shipped. I had to buy that much for length and I can either use more if this ever wears out, or use it on something else. It is heavy duty waterproof polyester in black. I cut it to length, spray glued and folded it in half along the length to double up the material and keep the edges that are frayed on the internal area.

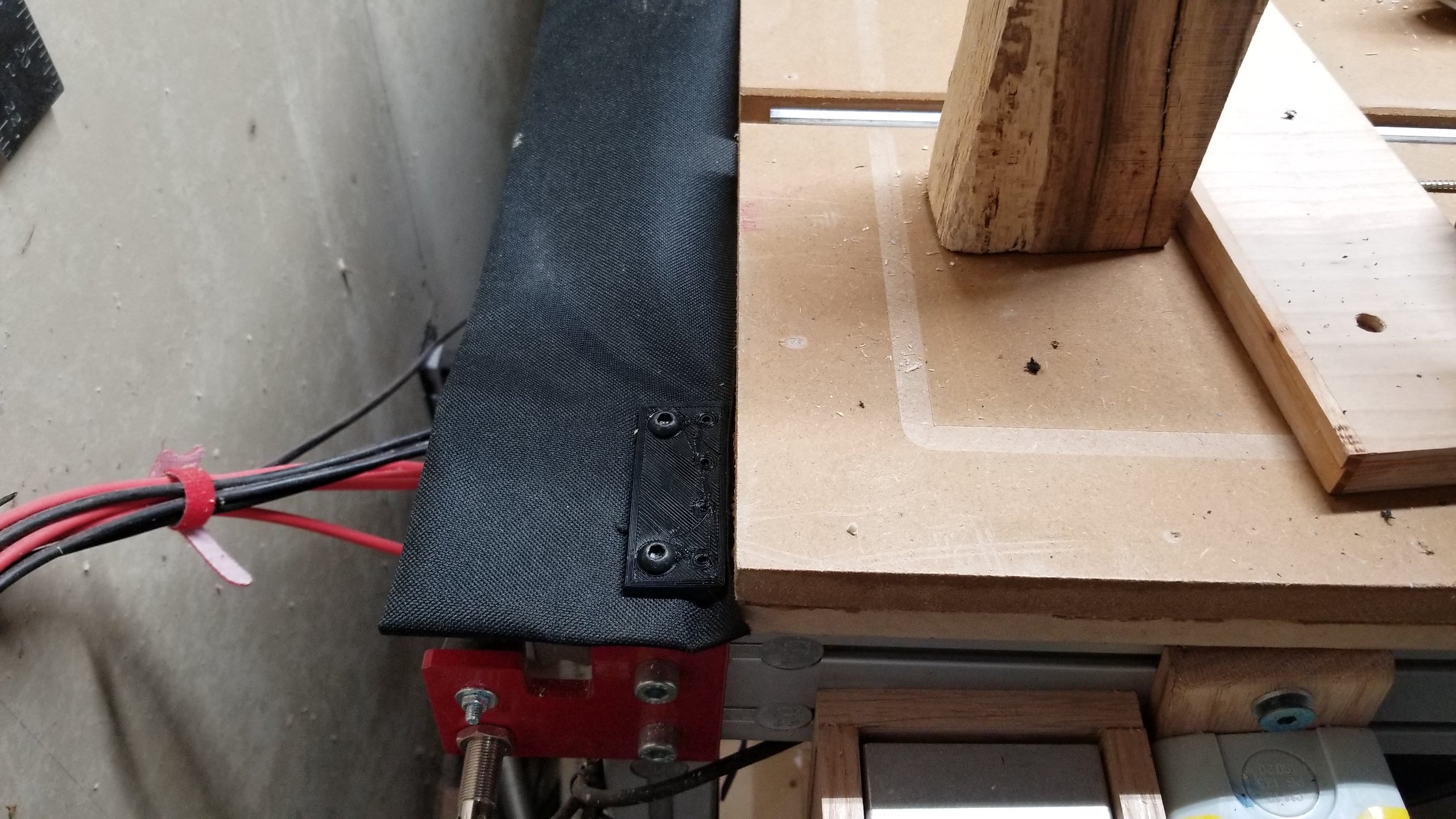

Then I designed a couple of plates to 3D print that would hold the fabric and attach it to the extrusion frame. They bolt onto the extrusioin, through the fabric using 2 6mm hammer insert nuts and 2 M6x20 bolts. 4 brackets on the 8 foot bed is enough to stretch the fabric tight and prevent any gaps between the extrusion and bed. It should catch anything without allowing it to go under the machine between the bed and extrusion. I left about 1/4 inch of fabric hanging off of the edge to butt up against the spoil board.

Now I have protection. Simple, inexpensive and hopefully prevents having to remove this gantry before I need to. I have tried to use a few different things to help in the past. I made a bracket with brushes that I hoped would wipe the rail as it cut, it kind of worked. It also took up space on the gantry and was not easy to remove when needed. Blowing the rails off constantly is another method I have seen online, but the expense and the noise prevented me from trying that. This works.

Leave a comment